Understanding 40 Shore: The Ultimate Guide to Membranes and Vacuum Systems

What is 40 Shore Hardness?

The term 40 shore refers to a specific measurement of hardness in rubber and polymer materials. The Shore hardness test measures the resistance of a material to indentation, and it is a standard scale widely used in various industries. A 40 Shore hardness indicates a medium-soft material that strikes a perfect balance between flexibility and durability.

This scale is part of the Shore durometer measurement system, which is divided into various scales, including Shore A, Shore D, and others. While Shore A is predominantly used for softer rubbers, Shore D is tailored for harder materials. A 40 Shore A rating suggests that the membrane is soft enough for applications that require flexibility but strong enough to withstand significant stress.

The Importance of Choosing the Right Membrane

When it comes to businesses that rely on vacuum presses or similar systems, the choice of membrane is critical. Using a 40 shore membrane can bring numerous advantages to your operation:

- Flexibility: 40 Shore membranes can easily accommodate varied shapes and surfaces, ensuring optimal performance.

- Durability: These membranes offer long-lasting reliability, reducing the frequency of replacements and maintenance costs.

- Resistance to Environmental Factors: Many membranes at this hardness level exhibit excellent resistance to heat, chemicals, and UV light.

- Improved Quality of Output: Using the correct hardness in your membranes can lead to a superior final product, enhancing your business's reputation.

Types of Membranes: Explore the Options

When selecting membranes for your vacuum systems, consider the various types available on the market. Each type has its unique properties and applications:

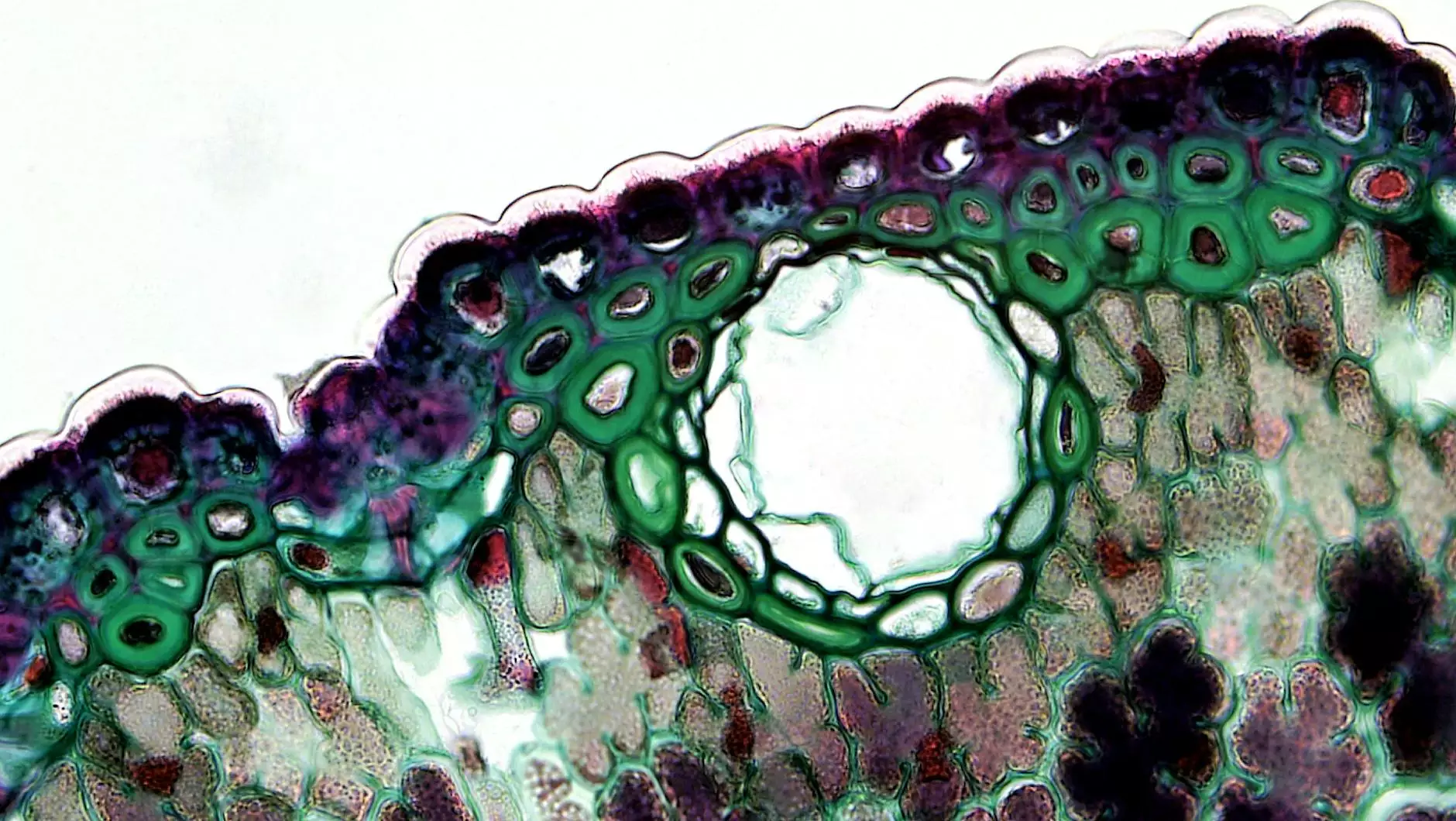

Silicone Membrane

Silicone membranes are renowned for their high-temperature resistance and flexibility. They can withstand extreme conditions and are incredibly versatile in application. For businesses dealing with food processing, silicone membranes are the preferred choice due to their non-toxic and FDA-approved status.

Rubber Membranes

Rubber membranes, particularly those rated at 40 shore, provide an excellent combination of elasticity and tensile strength. These are useful in various industrial applications, such as automotive or manufacturing processes where durability is crucial.

Natural Rubber Membranes

Natural rubber membranes are famous for their excellent grip and ability to conform to uneven surfaces. They tend to have a higher degree of elasticity, making them ideal for applications requiring a tight seal or specific pressure control.

Vacuum System Parts: The Backbone of Your Operation

A vacuum system is only as good as its components. Investing in high-quality vacuum system parts is essential for maintaining efficiency and ensuring longevity in your machines. Components such as seals, valves, and pumps all contribute to the overall effectiveness and should be chosen carefully based on your specific needs.

Choosing Quality Vacuum System Parts

When sourcing parts for your vacuum systems, it’s vital to consider:

- Material Compatibility: Ensure that the parts you select are compatible with your membranes and overall system.

- Durability: Invest in parts that can withstand the rigors of daily operations.

- Supplier Reputation: Work with suppliers known for high-quality components, such as vacuum-presses.com.

Applications of 40 Shore Membranes in Various Industries

The usage of 40 shore rated membranes extends across various industries. Here are some applications:

Manufacturing

In manufacturing, these membranes are often used in vacuum forming, where the ability of the membrane to conform to product shapes is paramount. The 40 Shore hardness provides just the right level of pliability and resistance to punctures.

Automotive Industry

Many automotive applications require seals and membranes that can handle harsh conditions. The durability and elasticity of 40 Shore rubber or silicone membranes make them ideal for use in various automotive components.

Food Processing

In food processing, hygiene and safety are of utmost importance. Silicone membranes, particularly those that meet the 40 shore hardness rating, are often utilized due to their non-toxic nature and high resistance to heat, making them suitable for use in cooking or packaging operations.

The Process of Selecting the Right 40 Shore Membrane for Your Business

Choosing the correct membrane for your vacuum systems isn’t just about hardness; it also involves considering various other factors:

- Thermal Stability: The membrane must withstand the temperatures it will encounter during production.

- Chemical Resistance: Depending on the materials you work with, the right membrane should resist degradation due to chemical exposure.

- Thickness: Membrane thickness can affect performance, especially in maintaining vacuum levels. Balance is key.

- Customizability: Depending on the application, having the option to customize the size or shape of the membrane is essential.

Best Practices for Maintenance of Vacuum Systems and Membranes

To ensure the longevity and efficiency of your vacuum systems and 40 shore membranes, regular maintenance is crucial:

Regular Inspections

Schedule routine checks on your vacuum systems to detect wear and tear early. Look out for any signs of damage on membranes or system parts.

Cleaning

Keep your membranes clean to avoid contamination. Use appropriate cleaning solutions that do not harm the material and prolong their lifespan.

Proper Storage

When not in use, store membranes in a cool, dry place, away from direct sunlight. Proper storage can prevent premature wear.

Conclusion: The Shift Towards 40 Shore Membranes

The shift towards using 40 shore membranes in various industries highlights the critical role they play in ensuring consistent quality and performance in vacuum systems. By investing in high-quality membranes and components like those available from vacuum-presses.com, businesses can significantly enhance their operational efficiency, improve product quality, and ultimately fuel growth.

Understanding the characteristics and advantages of these membranes is essential for any business looking to stay competitive. Whether you are purchasing membranes, silicone or rubber types, or vacuum system parts, make informed decisions to ensure your business thrives.