The Crucial Role of Auto Parts Manufacturers in Shaping the Future of Automotive Industry

In the rapidly evolving world of automotive technology, auto parts manufacturers stand at the forefront of innovation, quality assurance, and sustainability. These industry leaders are instrumental in shaping the safety, efficiency, and performance of vehicles worldwide. As the backbone of the automotive supply chain, their expertise and commitment influence not only the functionality of individual vehicles but also the future trajectory of the entire transportation sector.

Understanding the Landscape of Auto Parts Manufacturers

The auto parts manufacturing industry is a complex and highly competitive domain characterized by a diverse array of companies ranging from large multinational corporations to specialized regional suppliers. These manufacturers produce a broad spectrum of automotive components, including engine parts, transmission systems, electronic modules, braking systems, suspension parts, and cosmetic accessories.

Key factors that define leading auto parts manufacturers in today's market include:

- Focus on innovation and technology integration

- Commitment to quality and safety standards

- Adoption of sustainable manufacturing practices

- Strong supply chain management

- Ability to meet diverse regulatory requirements

The Evolution of Auto Parts Manufacturing in the Automotive Industry

From Traditional to Advanced Manufacturing Techniques

The journey of auto parts manufacturers has witnessed a significant transformation from traditional manual processes to advanced automation and digital manufacturing methods. Cutting-edge techniques such as robotics, 3D printing, and AI-driven quality control have revolutionized how components are designed, produced, and tested.

This evolution ensures that modern parts are not only more precise and durable but also produced at a faster rate, reducing costs and turnaround times. Additionally, smart manufacturing practices enable real-time monitoring of production lines, facilitating immediate quality adjustments and minimizing waste.

The Rise of Electric and Hybrid Vehicle Components

With the global shift toward electric vehicles (EVs) and hybrids, auto parts manufacturers are adapting by developing specialized components like high-capacity batteries, electric drive units, and power management systems. This shift requires extensive R&D efforts to innovate durable, lightweight, and high-performing parts tailored specifically for EV architectures.

How Auto Parts Manufacturers Drive Innovation and Quality

Investing in Research and Development

Innovation is the cornerstone of competitive advantage in auto parts manufacturing. Leading companies dedicate substantial resources to research and development, exploring new materials, manufacturing processes, and design concepts to improve vehicle performance and safety.

For example, the integration of lightweight composites and advanced alloy materials not only enhances fuel efficiency but also reduces greenhouse gas emissions. Additionally, the incorporation of IoT and sensor technologies allows for smart parts that can communicate vehicle health status and predict maintenance needs.

Adhering to Robust Quality Standards

Supply of reliable automotive parts necessitates unwavering adherence to quality standards such as ISO/TS 16949, IATF 16949, and OEM specifications. Top-tier auto parts manufacturers implement rigorous testing procedures, including durability assessments, electronic compatibility tests, and safety validations.

This meticulous approach minimizes recalls, enhances brand reputation, and ensures consumer safety.

Sustainable Manufacturing: Paving the Way for a Greener Automotive Industry

Eco-Friendly Materials and Processes

Sustainability has become a vital aspect of auto parts manufacturing. Manufacturers are increasingly adopting eco-friendly materials like recycled plastics and metals and optimizing processes to reduce waste and energy consumption.

Reducing Carbon Footprint

Leading companies implement green initiatives such as renewable energy usage in factories, water recycling, and waste management systems. These efforts contribute to a significant reduction in carbon emissions, aligning automotive supply chains with global environmental goals.

The Importance of Strategic Global Supply Chains

Effective auto parts manufacturers operate within complex global supply networks that enable cost-effective production and timely delivery. This global footprint facilitates access to a wide range of raw materials and technological expertise, ensuring continuous innovation and supply stability.

Furthermore, resilient supply chains help mitigate risks related to geopolitical tensions, tariffs, and disruptions such as pandemics, ensuring consistent availability of critical automotive components.

The Impact of Technology on Auto Parts Manufacturing

Automation and Digitalization

The adoption of Industry 4.0 principles—such as automation, IoT, and data analytics—has greatly enhanced manufacturing efficiency. Automated processes reduce human error, improve precision, and lower costs.

Artificial Intelligence and Machine Learning

AI-driven systems enable predictive maintenance, quality control, and demand forecasting, allowing auto parts manufacturers to optimize production schedules and inventories. These technologies also help in designing innovative parts that meet strict performance standards.

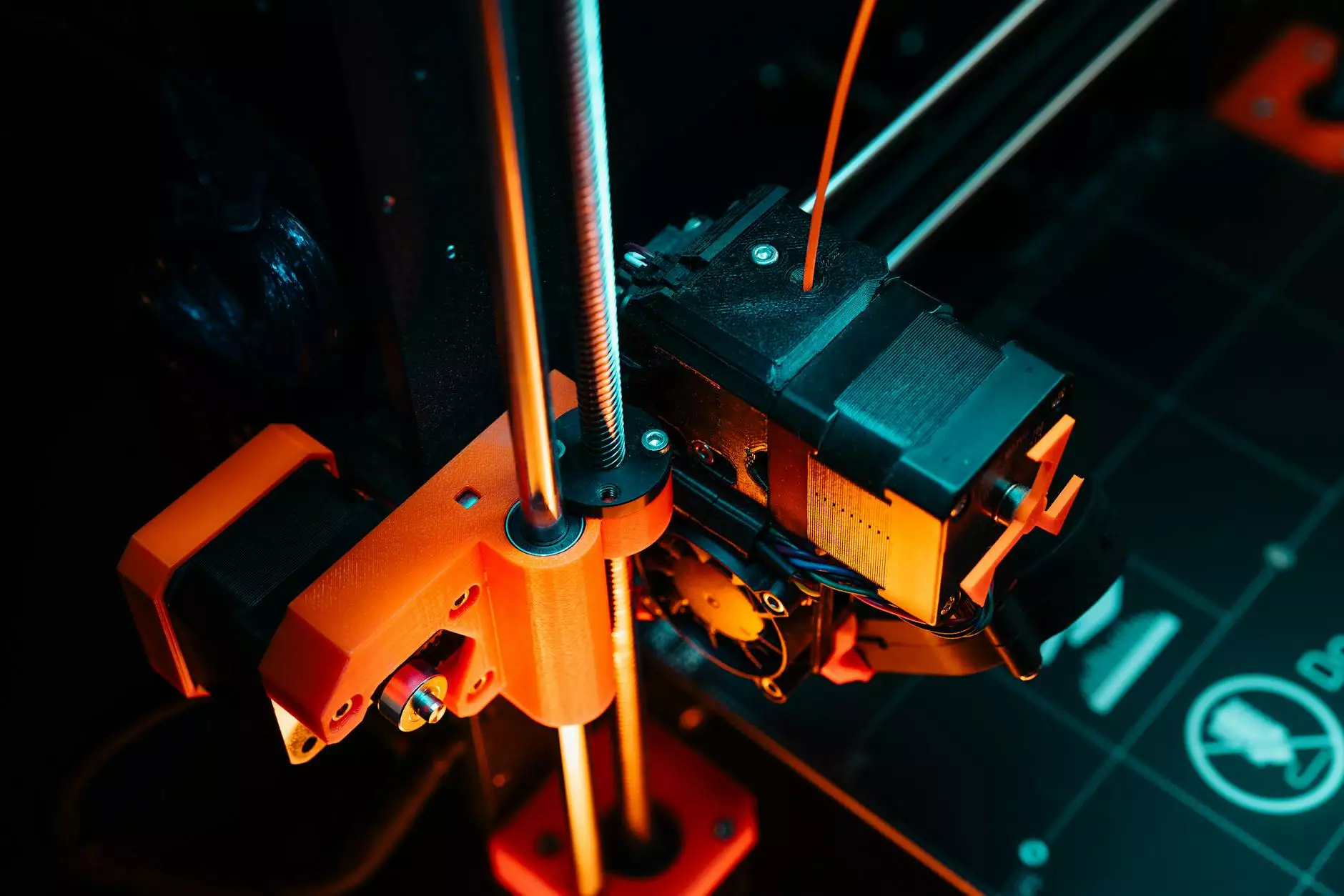

3D Printing and Rapid Prototyping

3D printing allows for rapid prototyping of new parts, enabling faster testing and iteration. This technology accelerates product development cycles and sparks innovation in complex component design.

Future Trends in Auto Parts Manufacturing

- Electric Vehicle (EV) Components Development: As EV adoption grows, manufacturers are focusing on developing new battery technologies, cooling systems, and high-voltage electrical parts.

- Autonomous Vehicle Parts: Building sensors, cameras, and AI modules to support self-driving technology.

- Smart and Connected Parts: Integrating Internet of Things (IoT) features for real-time vehicle diagnostics and maintenance alerts.

- Sustainable and Circular Economy Initiatives: Emphasizing recyclable materials and designing for disassembly.

- Global Supply Chain Optimization: Using blockchain and AI to increase transparency and resilience.

Why Choose a Trusted Auto Parts Manufacturer Like IMA Auto Parts?

At imautoparts.com, we pride ourselves on being a reliable auto parts manufacturer specializing in high-quality automotive components. Our extensive experience, innovation-driven approach, and commitment to sustainability ensure that our clients receive parts that not only meet but exceed industry standards.

Partnering with a trusted manufacturer like IMA Auto Parts ensures:

- Consistent product quality through rigorous testing

- Access to latest technological advancements

- Flexible customization options

- Timely global delivery

- Competitive pricing and dedicated support

Conclusion

The landscape of auto parts manufacturing is dynamic and continues to revolutionize how vehicles are designed, built, and maintained. As the industry shifts towards electrification, automation, and sustainability, auto parts manufacturers play a critical role in driving innovation and ensuring safety, efficiency, and environmental responsibility.

Choosing the right manufacturing partner, such as imautoparts.com, can provide a significant advantage in staying ahead in this competitive industry. By leveraging cutting-edge technology, maintaining rigorous quality standards, and embracing sustainable practices, auto parts manufacturers will continue to be pivotal creators of the future automotive landscape.

Get in Touch with IM Auto Parts Today!

Explore our wide range of high-grade automotive parts designed to meet your specific needs. Together, let's drive innovation and quality forward—building a safer, more efficient, and greener future for automotive industry worldwide.